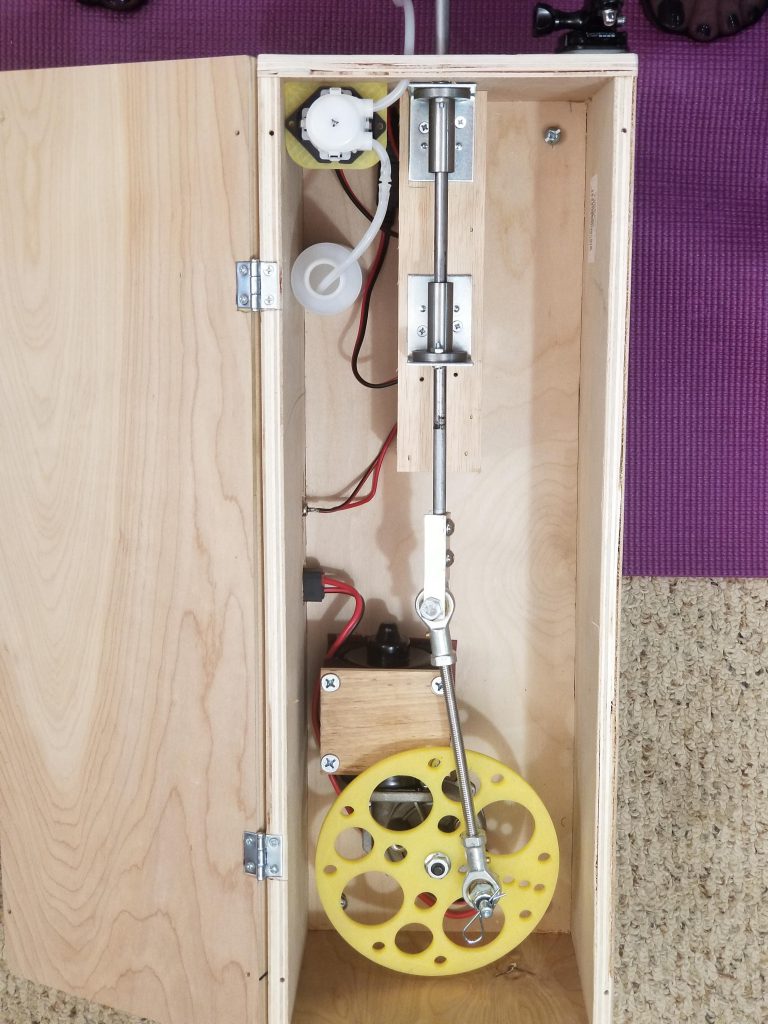

So yeah, when the machine stops fucking mid session it is really no fun. Then you’re just like a primative trying to do things manually… Anyway, the cause of the issue was:

- The heat generated by the wiper motor in an enclosed case, caused some expansion of the 3d printed flywheel

- The rotation of the flywheel was clockwise which allowed the nut to get loose.

Because of those two, the nut that secures the flywheel down to the small gripping area of the motor shaft got loose, and the fucking machine thrusts became irregular, or not at all as the flywheel was no longer rotating.

The solution is a new part. I re-designed the 3d printed part to fit around a 5/16th nut, and reversed the polarity of the motor, causing the flywheel to run in a counter clockwise direction.

The outside of the area that captures the nut fits a 19mm socket, so it can be threaded onto the motor shaft and tightened. Should try and see if I can break it again 🙂